Flexible and Advanced Manufacturing in Automotive Sector

28 July,2023 - BY admin

28 July,2023 - BY admin

Flexible and Advanced Manufacturing in Automotive Sector

It is widely known in the automotive sector that OEM customers strongly demand for lowering manufacturing costs, reduced logistics costs, lighter weight structures, new material requirements and a higher level of quality. Manufacturers of components for the transportation sector are studying the development of new technologies that will enable them to manufacture lighter and safer components, relying on the use of design and manufacturing tools that will enable them to produce lighter and safer components.

The following international trends are pushing production systems to their limits: Personalization, Globalization, Financial markets, Aging workforce, Sustainability, Population and middle-class growth, Information society and Urbanization.

These generic needs translate into the following short- and long-term industrial needs:

- Customers strongly demand competencies in lower manufacturing costs, reduce logistics costs, lightweight structures, new material competence and superior quality level.

- High demand for OEM quality to define the right means to ensure process capability and efficiency.

- Several projects are required that come to include this type of system or ensure dimensional quality and process capability monitoring.

- Zero defects at all stages.

- Develop a measurement system in the in-line production system for complex product Reusable modular system.

- Open and flexible system programmable by plant technicians.

- Cloud monitoring of all production locations of multi-stage manufacturing production lines.

The structural changes that have taken place in the automotive industry from the late 1980s to the present day have led to various organizational and technological changes in automotive manufacturing companies:

- Reduction in the number of components.

- Standardization of the manufacturing processes for parts and components.

- Reduction in the size of the series.

- Increased variability in the number of models produced.

- Increase in the level of automation.

- Increased purchases by automakers from suppliers.

- Reduction in the number of first-tier suppliers.

Therefore, all the uncertainty in terms of being able to quantify the diversification of vehicle drive systems, with implications in structural elements even for the same model and range, as well as the great diversification and customization in OEM models soon makes the number of references to handle grow exponentially, making it clear the need to radically change the manufacturing concept.

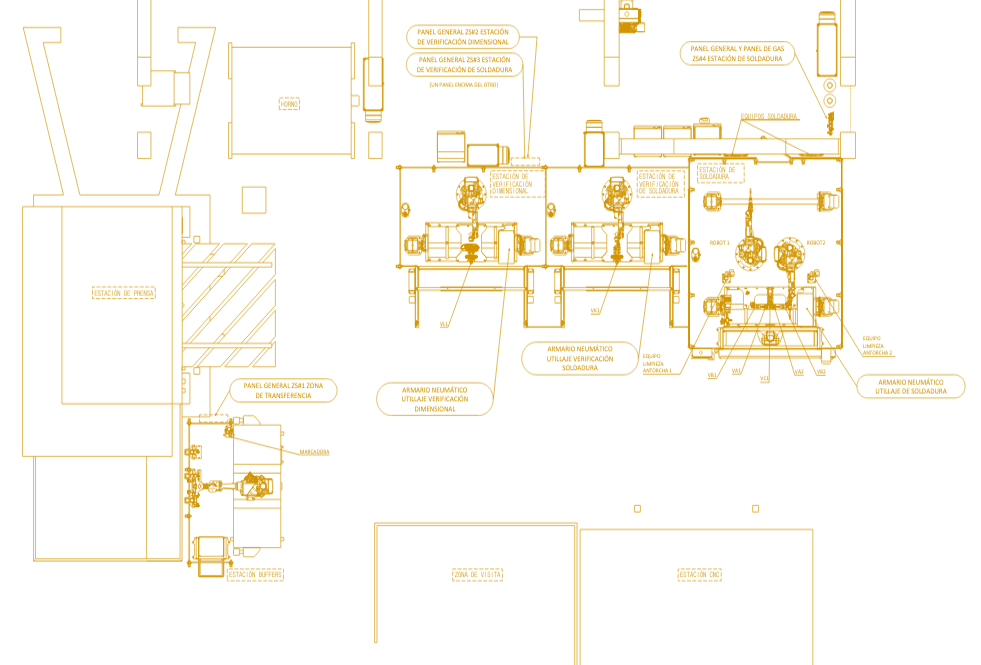

To this end, AIC and its Automotive Smart Factory have been working on developing different concepts around this objective for the last few years:

- Advanced tools for production flexibility, visualization and control.

- Advanced automation and robotization (intelligent and collaborative).

- Flexible and intelligent tools for line control.

- Artificial vision verification and inspection systems.

- Traceability of raw materials and parts (in process and finished).

- Digitization of strategic machinery and equipment installations.

- Data processing in 5G environments

In the ODIN project, AIC has worked on flexible manufacturing, offering different process options within an automated line such as the inclusion of inspection process within the existing manufacturing process (ODIN Automotive pilot, operation 3).

Get the latest news on ODIN right to your inbox!

Newsletter Permission: The ODIN project will use the information you provide in this form to be in touch with you and to provide updates and news. Please let us know if you would like to hear from us:

ODIN newsletter: You can change your mind at any time by contacting us at info@odinh2020.eu. We will not distribute your email address to any party at any time.

Comments (0)