Flexible Workstation in the assembly line of White Goods

17 June,2023 - BY admin

17 June,2023 - BY admin

Flexible Workstation in the assembly line of White Goods

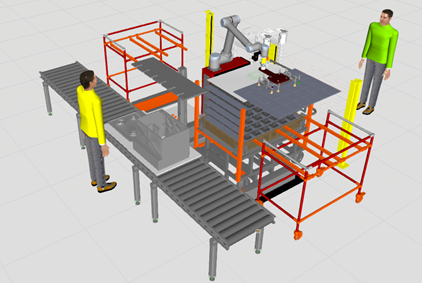

In the ODIN project, Whirlpool is exploring a disruptive innovation that meets the digital transformation needs of the company and can make the white goods production process even more efficient. Digitalisation, Virtual simulation and virtual commissioning are used to reprogram/ reconfigure a robot for a new product variant in order to integrate new processes, to teach new interaction schemes with humans and to replicate the solution to similar cases with minimum cost/effort.

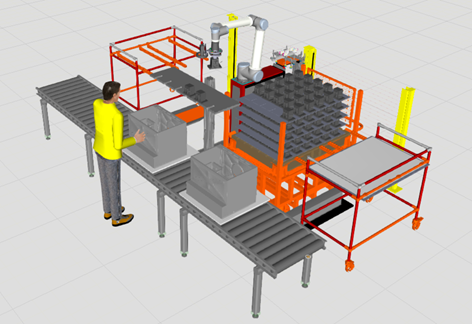

Whirlpool is exploiting the Digital Twin of the physical robotized workstation that manages one component (transformer) in a physical space: the cobot and worker coexist without any physical barrier to let the operator pick and install it inside the microwave oven, which is moving on a continuous flow assembly line. The Digital Twins allows Whirlpool to have the exact virtual representation of the real workplace, a quick and safe testing of various solutions or several constraints and to transfer the selected solution to the real lab environment for a final close-to-real validation.

Picture 1: Digital Twin of the workstation in the AS-IS situation, i.e. with one product variant in the assembly line (Visual Components tool)

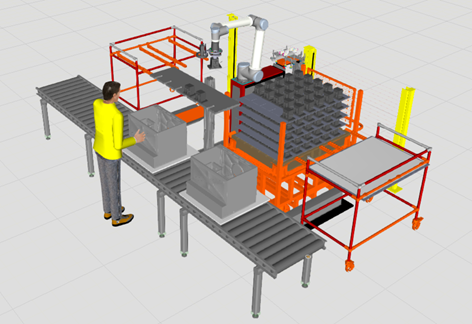

Thanks to it, Whirlpool is evaluating possible improvement through the addition of new sensors, functionalities, hardware changes (new robotic arm, different gripper, etc.) and test in different scenarios. The final aim is the introduction of a new product variant along the assembly line giving to the workstation and to the assembly line the flexibility to change operations at any time with several benefits for the production process.

Picture 2: Digital Twin of the workstation in the TO-BE situation, i.e. with two product variants in the assembly line (Visual Components tool)

A demonstration in the real world of the Digital-Virtual simulation is needed, thus Whirlpool will test the distance between the simulated and the real performances and the innovative functionalities.

Get the latest news on ODIN right to your inbox!

Newsletter Permission: The ODIN project will use the information you provide in this form to be in touch with you and to provide updates and news. Please let us know if you would like to hear from us:

ODIN newsletter: You can change your mind at any time by contacting us at info@odinh2020.eu. We will not distribute your email address to any party at any time.

Comments (0)