“DO IT YOURSELF” Reliable DGH Deep Learning tool for industrial quality inspection processes

05 May,2023 - BY admin

05 May,2023 - BY admin

“DO IT YOURSELF” Reliable DGH Deep Learning tool for industrial quality inspection processes

DGH, throughout all our 40 years of experience, is deploying its expertise in two complementary ways of business related with manufacturing industry. Firstly, our Engineering Division delivers automatic industrial installations based mainly on robotics, and secondly, the Maintenance Business Unit offers complete outsourcing industrial maintenance services. Both businesses let us have accurate insights of needs from end users of several sectors, and our Innovation and Technology Department merges this valuable information with our capabilities to offer innovative and useful technical proposals that can be implemented on production lines with affordable ROI’s.

Under these mandatory premises, ODIN has provided DGH an amazing framework in which we have had the chance to collaborate with partners from all over Europe and share our experience and our point of view with them to handle different challenging issues. Particularly, we have figure out how Deep Learning tools for quality inspection with 2D cameras could be deployed in different sectors, with a standardized and effortless procedure.

To do so, DGH has developed and tailored for the ODIN Automotive use case a complete software that aims to help non-experienced end users throughout all necessary steps to run successful and affordable quality inspection controls by using Deep Learning tools and 2D cameras.

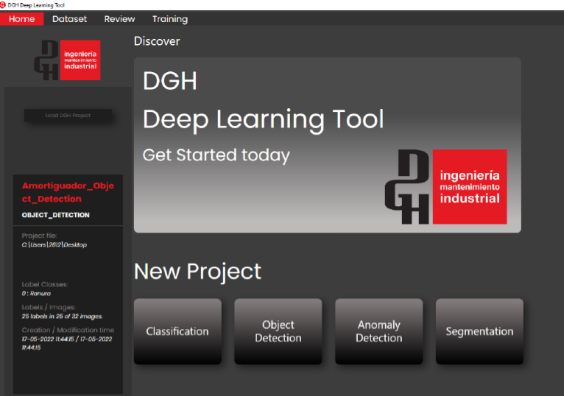

A first application called “DGH Deep Learning Tool” guide the end user with:

- To process and classify dataset of images in an easy way.

- To decide the right Deep Learning strategy with the four main available tools: Classification, Object Detection, Anomaly Detection and Segmentation

- To develop the neural network and validate it before implementing it in the production line

The second application, called “DGH Production Tool”, is a Human-Machine Inteface that let the operator keep controls updated and collect processed information about quality of products that can be useful to solve malfunctions within manufacturing process.

Hopefully, we hope this development will help the ODIN consortium to achieve its goals and their dissemination will make some European companies be aware about how they can put their productivity up to next level.

Get the latest news on ODIN right to your inbox!

Newsletter Permission: The ODIN project will use the information you provide in this form to be in touch with you and to provide updates and news. Please let us know if you would like to hear from us:

ODIN newsletter: You can change your mind at any time by contacting us at info@odinh2020.eu. We will not distribute your email address to any party at any time.

Comments (0)