Safety, security and advanced sensors: the keys to the automation of the present and future

03 October,2021 - BY admin

03 October,2021 - BY admin

Safety, security and advanced sensors: the keys to the automation of the present and future

As a long-time Safety leader, PILZ is constantly keeping up with the advances in the industry and paying attention to the topics that will shape the future of machinery. We know this future includes interconnected machines, data-driven processes and more autonomous systems. However, with them comes the ever important topic of Security.

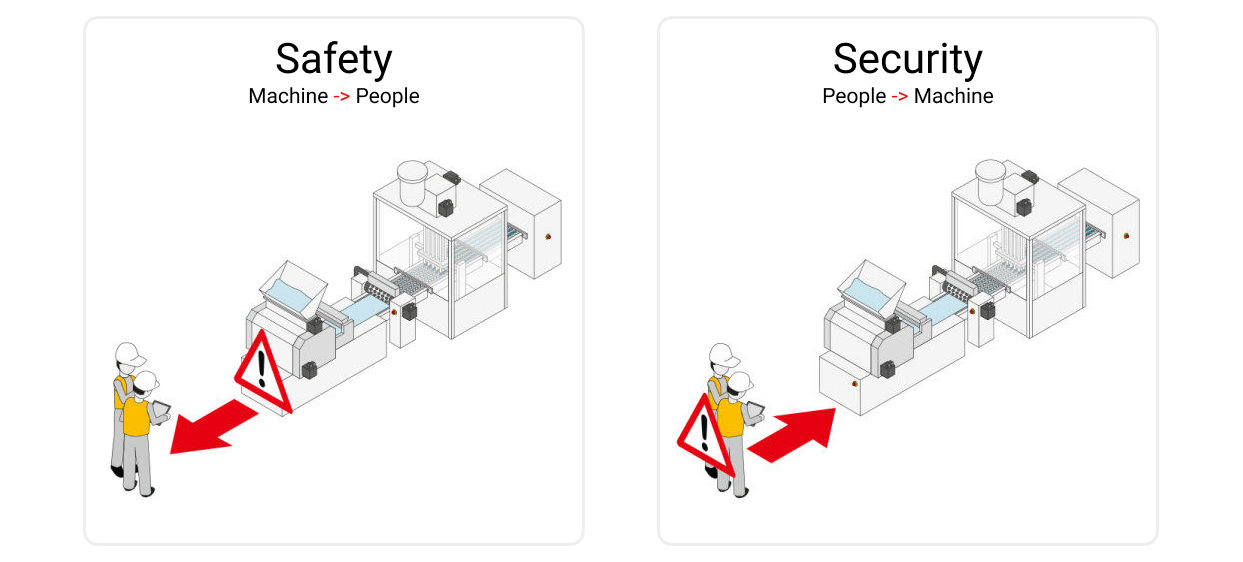

What’s the difference between Safety and Security?

At a high level, we can describe safety as the protection of people from the hazards that emanate from plant and machinery. In contrast, security can be seen as the protection of plant and machinery from manipulation and misuse.

With this in mind, safety and security have been relatively isolated in the past. As long as all of your components had the proper Performance Level, and within the safety lifecycle, you could consider your machine safe. However, the reality is that machines, robots and entire plants are interconnected, and therefore vulnerable to IT attacks or malfunctions. Therefore, there is no safety without security, and the line between them is blurring more and more. This is why It is very important to guarantee the availability of plant and machinery and the integrity and confidentiality of machine data and processes.

In order to have a machine that is both safe and secure, It becomes increasingly important to have a holistic view, and consider an industrial security lifecycle. Here are six tips to improve your industrial security:

- Deference in depth

- Organizational measures

- Training

- Segmenting

- Firewalls

- Patch Management

You can find more details about these tips and industrial security here.

Advanced sensors, a new challenge in safety

In ODIN, there are innovative solutions related to sensor technology by means of new advancements. However, this poses an interesting challenge for safety compliance.

Typical sensors work with electronic signals and are certified and evaluated according to IEC EN 62046 and ISO EN 13849-1. Some examples include optoelectronic sensors, such as light barriers, laser scanners or even radars.

Get the latest news on ODIN right to your inbox!

Newsletter Permission: The ODIN project will use the information you provide in this form to be in touch with you and to provide updates and news. Please let us know if you would like to hear from us:

ODIN newsletter: You can change your mind at any time by contacting us at info@odinh2020.eu. We will not distribute your email address to any party at any time.

Comments (0)